In Iceland, you have to check normal passenger cars with this frequency:

4-2-1

, that is new car waits 4 years, has 1 check, waits 2 years and then is checked every year. My wife’s car is in the “every year” category. Usually it passes with “this car looks damn good!” – but a couple of years ago we had it in for service (change starter) and the service personnel managed to crash the car (rather badly). As the insurance company didn’t want to cough up what we thought at the time to be fair for the car, the company that damaged the car decided to step in and offer to fully fix the car. It looked well done when we received the car – I’m not so sure afterwards. In April I took the car in for its yearly checkup. Apparently everything is good – except the Sill – it’s lost its strength. So, green ticket (means I must fix and re-check within 2 months).

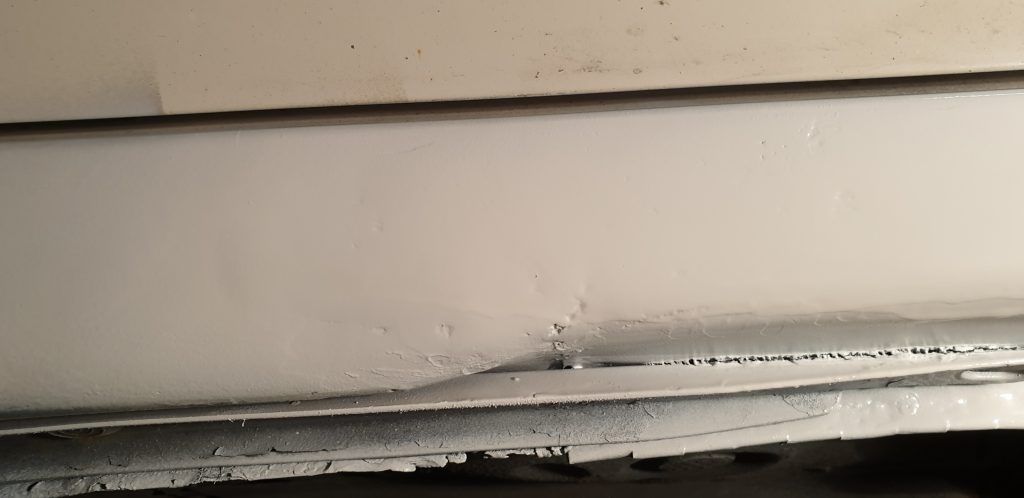

The Sill at the back

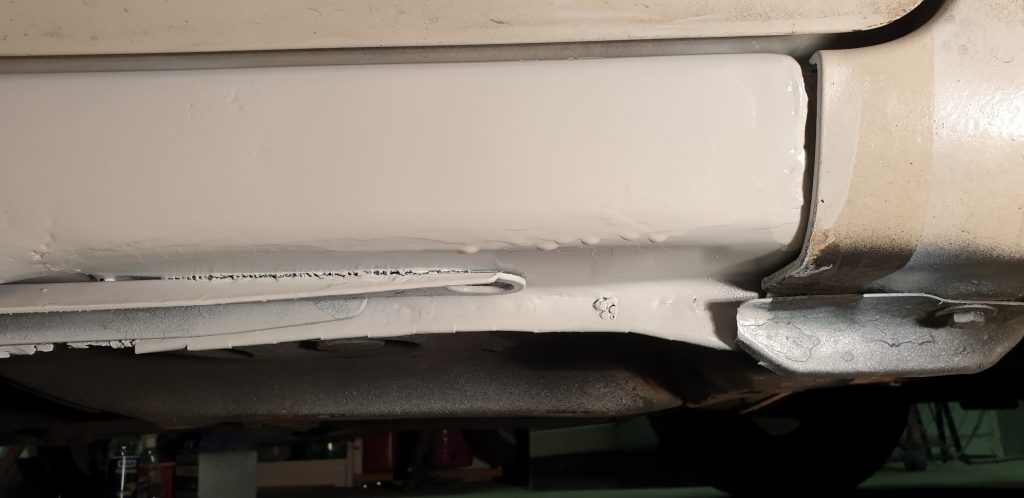

The Sill at the front

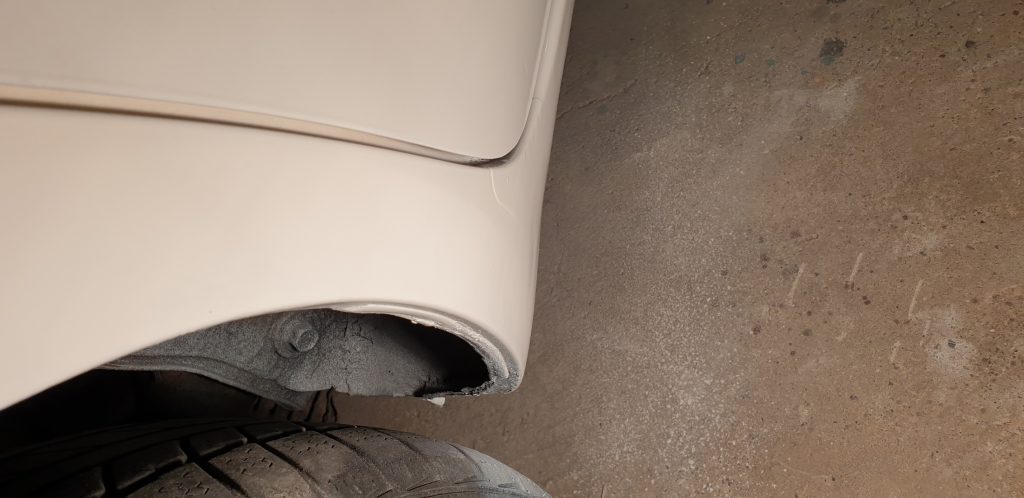

The previous pictures are how they used to look. I wasn’t sure how bad it really was, so I sanded down the rust and painted because we didn’t want the car to look bad (on a day-to-day basis). So the images below are how it looked when the checking station got the car to them.

It’s apparent that it’s not right – but little did I know. So, I sent the pictures to a couple of workshops and got offers for 150.000 ISK (US$1203) which I found a bit high considering the car would not fetch even double that at best. But there was a way – DIY. I wasn’t quite sure though that I could – but hey, it was worth a try, and I’m a man willing to try most things at least once. It’s been more than 30 years since I welded last time and then it was stick welding in 3mm galvanized – so not much of a comparison. I ordered myself a gasless MIG (yes, the irony is not lost on me – MIG is Metal-Inert-Gas) from China and was pleasantly surprised when the unit I got fulfilled all of my hopes. I did some test welds with it on fresh 0.6mm and 0.8mm material and found that on fresh material it wasn’t much of an issue. Several YouTube videos later, I thought I was ready. The car was brought inside and the work started. First I had to cut and clean as much as I could. I tried not to waste – so I cut what I could punch through using an awl. I didn’t realize then that what the awl couldn’t get through would still be on the thinner side.

Cutting the rear

Lots of strength loss

And fitting a piece over the cut

There was quite a lot of material that I cut away. What did help was that in my youth I used to work as a tinsmith (blikksmiður), so working and reshaping sheet metal wasn’t at all uncomfortable to me. I didn’t have all the nice tools I used to have, but I did have a hammer, wood and a metal table. And so the shaping began. The rear ended up being 5 pieces of 0.8mm sheet cut and shaped for the best results. Welding the pieces in place was… interesting. Most of the time it didn’t work like when I tried welding the fresh sheet pieces together. The welder was sputtering (alleviated by changing the amperage and feed speed) and the car metal was in some places literally disintegrating. Many places required hole-filling and one time goop that had been put inside the Sill earlier caught fire – I had a good run fetching the extinguisher and fill my garage with blue fire-retardant powder 😂. The welds were then cleaned up and primed ( It would take me 3 week-ends to finish up the car).

Closed up

Protected

Welds barely visible

But here

You can see how ugly the welds are

Because

It takes a lot of effort and practice to get it right.

And for the front…

This was

ONE picece and a small patch.

Ugly weld

but nice result

The last week-end was then used to clean up the work, add some filler (totally I added about 100g of filler to the car), prime everything, paint it and put rock protection where I could. This is the result before the rock protection

And the final result…

Bottom line – I learnt a lot (including respect for the work autoshops are doing) – and including that I can do it myself – even if it’s not eye-catching perfect, it’s good. And the guys checking the car thought so too (and they were genuinely impressed that I didn’t try to cheat my way around it!)

5/5 – would do again.